Performance Parts

Lotus Esprit SE

Toyota MR2

Technical Articles

Diagnostic Tools

Turbo Systems

Upgrades

John's Projects

'91 Esprit SE

'87 MR2 Turbo

WC Engineering

Service Work

News & Updates

FAQ

Contacts & Ordering

Links & Testimonials

Compression and Leak Down Testing

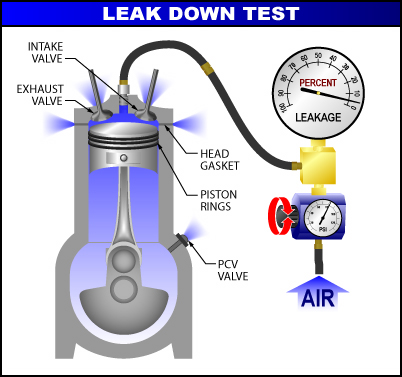

A very important piece of information about the internal condition of an engine is a leak down test. This test is very different from a compression test. We will try to explain the differences and the reasons for the tests.

Compression TestA compression test is done (obviously) with a compression gauge. This is basically a pressure gauge that has a one-way check valve and an adapter to screw into a spark plug hole. With a good battery and a warm engine, we remove all the spark plugs. The compression tester is screwed in place of one spark plug and while holding the throttle plate open, the engine is cranked over. The engine is allowed to rotate a few times to build up pressure and this pressure is recorded. Each of the cylinders are checked in the same way.

Illustration by Adastra Design |

In our opinion, all cylinders should be within 4% of each other. If you have a cylinder that has excessively low compression, try adding a few drops of oil. If the compression comes up, you have a ring seating problem. If it does not, you have a valve or head gasket problem, or some other problem.

Benefits:Drawbacks:

Leak Down Test

A leak down test is more specific in pinpointing the condition of an engine and if there are problems, it can pinpoint the needed area of attention. A leak down test is performed with a special gauge and manifold set. It consists of a calibrated pressure gauge and a pressure regulator and adapters to connect it to the spark plug hole. Compressed air (or nitrogen) is fed into the gauge and the gauge is calibrated against a zero reference (no air leakage). The adapter is then screwed into the number one spark plug hole (with cylinder #1 at TDC compression) and the gauge is attached. As soon as the gauge is attached to the adapter air will begin to fill the cylinder. As this happens, the gauge will begin to indicate the amount of air flowing into the cylinder.

Illustration by Adastra Design |

If air is leaking past the rings, or the valves, or the head gasket, we can directly read the amount of leakage and can easily find the leak. If there is air blowing out the PCV, we have a ring leak, if it's coming out of the exhaust, we have an exhaust valve leak, and so on...

FYI: All Lotus 907 engines with 25,000 miles or more that I have worked on have had an exhaust valve leak on #4 and sometimes #3.

A leak down test is especially good at discovering leaky valves. We use much less pressure (about 80 psi) than is normally in the combustion chamber (several hundred psi). If there is a valve that is slightly off its seat, the actual combustion pressure may have helped close it, but the lower testing pressure won't exert as much force and the leak will be apparent.

This test is very time-consuming with the engine in the car. To do the test, each cylinder must be tested one at a time, they must be at TDC compression, and the crank must be held in place to prevent rotation. A freshly rebuilt engine should have less that 4% leak down on each cylinder and if leak down is above 10%, service should be performed. All cylinders should be within 2 percentage points of each other. NOTE: These figures are for performance engines. Stock production engines may have as much as 10% right off the assembly line.

Benefits:Drawbacks:

If you ask your shop to do a leak down test, they may offer to do a compression test or may hesitate or quote a high price for the work. This is not uncommon -- it is not a simple task. If the shop that you use doesn't know what a leak down test is, then you should leave quickly and politely and never return. They do not have the proper diagnostics knowledge to be working on your engine.

I will add that every engine that I have done a leak down test on has been on an engine stand. The Lotus 4-cylinder 907 engine is very easy to test this way. If you pull the cam towers, then all of the valves are closed, making every cylinder in compression. The Toyota engines can be done similarly by removing the camshafts, others can be done by removing the rocker shafts. Removing the camshafts, rocker shafts, or cam towers is typically required to remove the head anyway, so during a tear down and rebuild, a leak down test is a simple task to perform.

© 2009 WC Engineering LLC, Website Design by Adastra Design