Performance Parts

Lotus Esprit SE

Toyota MR2

Technical Articles

Diagnostic Tools

Turbo Systems

Upgrades

John's Projects

'91 Esprit SE

'87 MR2 Turbo

WC Engineering

Service Work

News & Updates

FAQ

Contacts & Ordering

Links & Testimonials

Ceramic Ball Bearing Turbo Upgrade Kit

Ceramic Ball Bearing Turbo Upgrade Kit

Item #17201-17070

Price: $1637

Status: Limited Availability [Why?]

Core Charge: $800 (US customers)

or $1300 (foreign customers)

This is the highlight of our products, this turbo is the piece that belongs on the S4 Esprit. I'll try to provide some technical data about the stock system, and its weaknesses, and address the solutions.

When Lotus designed the S4, they used some of the best parts they had available and, at the time, the turbo selection used for the S4 Esprit was appropriate for its performance. However, there have been advances in turbocharger technology since that can make the Lotus Turbo Esprit even better. Let's look at the stock system and see what can be done.

The Factory System

It's a 2,2L 4-cylinder engine with a Garrett Air Research T-3 turbo, standard oil bushings, 0.63 AR "Lotus only" turbine housing with integral waste gate, standard T-3 compressor housing, and a 40 trim compressor wheel, oil fed and water cooled (on most). This compressor section can flow 30 lb/min of air or about 390 CFM at 15ºC. At this flow the unit can support 261 HP.

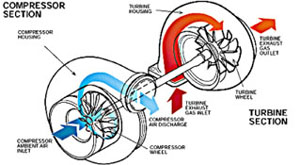

The turbo consists of three main parts. The turbine section contains the turbine wheel and this is where the exhaust flows through. The compressor section contains the compressor wheel and is where the intake air flows through. Lastly, the center section carries the water and oil and has the shaft that connects the turbine wheel to the compressor wheel. It also has the bearings, or bushings as the case may be.

Garrett Air Research |

The turbo in its stock form can flow enough air through the compressor to sustain 15 psi of boost with a nominal discharge temperature for only 7 seconds before the discharge temperature rises dramatically. This is from a small compressor wheel which is a compromise bewteen spool up and performance. It has often been observed that you can hold "1 bar" of boost, but as the RPMs rise the boost falls off. This is due to the small compressor wheel working outside of its limits. The turbine side can flow about 410 CFM of exhaust gases before the back pressure rises beyond acceptable limits.

Translation: The engine can only make the stated 264 or 280 horsepower for about 6 seconds before the systems "catch up" with each other. Then, as the intake temp rises, the exhaust back pressure rises and the power falls.

The engine, in its stock configuration, can only run at a sustained 247 HP constant.

What can we do to improve this?

The first idea most people have is to "turn up the boost" and that is not really the answer. The system needs to be addressed as a whole. Let's start with the turbo's compressor section. We need to get a more efficient compressor wheel that can sustain the volume of air desired and the boost desired. This will require a larger compressor wheel. Unfortunately, a larger compressor wheel will also have more turbo lag.

The next item is the turbine section. If we get more air into the engine, we will need to get more air out of it as well. We can address this in two different ways: we can machine the turbine wheel slightly or "clip" it, which will allow more flow, or we can machine out the turbine housing and install a larger turbine wheel. Both of these are viable realistic options as they will both allow more exhaust flow. However, as with the larger compressor wheel, both options will induce more lag... and a longer spool up time.

So far, we have solutions that will get us more power, but at the expense of spool up time.

Our Solution

Then, we look at ceramic ball bearing center sections. The stock center section only has oiled "bushings" supporting the connecting shaft and there is quite a bit of drag associated with it. When using a ceramic ball bearing assembly in the center section this parasitic drag is reduced down so low that it is negligible.

We can use a ceramic ball bearing center section, along with a larger compressor wheel and a modified turbine section, to get more volume, more flow, and faster spool up than a stock turbo.

This is exactly what we have come up with. Using a ceramic ball bearing center section, WC Engineering assembles a modified turbine section with a machined compressor housing and a larger compressor wheel (larger than the S4s wheel) to produce a turbo that offers improved spool up response, more efficient boost with lower charge air temperatures, and a more free flowing turbine section. This compressor section can flow 41 lbs/min of air or about 535 CFM at 15ºC. This is enough to sustain 357 HP with transient peaks around 375 HP.

Benefits are:In addition, the unit that we supply is a DIRECT bolt on. All of the factory hoses fit EXACTLY as the stock turbo does. There is no fabrication of brackets or lines, the exhaust down pipe is exactly as stock, and the intake hose is the same. From the outside, the unit appears completely stock.

The unit ships with a detailed, illustrated instruction set, including a list of needed tools. All the necessary gaskets are also included. All units are dynamically balanced at over 70,000 RPM.

This item requires the return of your used original turbo to WC Engineering. There is a core charge on the item.

© 2009 WC Engineering LLC, Website Design by Adastra Design